Strong but also visually appealing connections: Both were deciding factors for the production of the new electronic fabric refresher FreshUp. In order to meet them, BSH Hausgeräte GmbH chose ultrasonics as the most suitable joining technology. Herrmann was involved in the project at an early stage and was able to develop a welding solution together with BSH that completely fulfilled the manufacturer's wishes.

The challenge

The shiny MABS material of the case shells conducts ultrasonics very well, so that strong vibrations not only occur in the joining zone, but also in the entire component during the welding process. This caused marks to appear on the surface at various points where the component lies in the fixture.

Another customer request was a strong connection over the entire length. But there was only a small welding path of three tenths of a millimeter available – about half as much as would normally be used. It was not possible to adapt the injection-molding tool in the area of the energy direction without making changes to the appearance of the case shell.

Our solution

- Material: Special casting resin for the fixture dampens the vibration of the ultrasonics

- Design: By dividing the fixture into four segments we ensured accurate welding

- Parameters: Optimization of joining speed an other key welding parameters in joint DOE process ensures strong connections

Fixture allows flawless connection

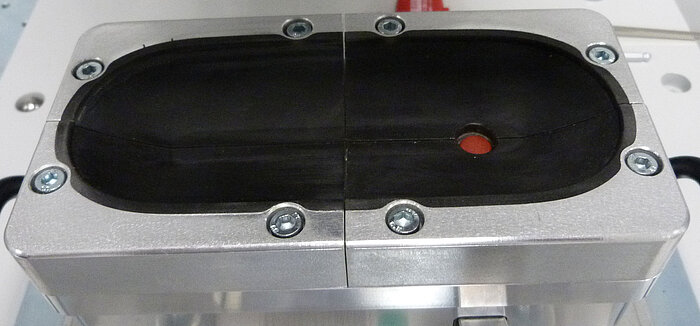

To dampen the vibrations of the welding process, the fixture was made of a special casting resin. This is an abrasion-proof, heat-resistant material with a hardness of 80 to 90 Shore - roughly equivalent to the hardness of skateboard wheels.

Further optimization of the fixture was achieved by dividing it into four fixture segments instead of the usual two. This structure ensures that the component lies cleanly in the fixture and can be welded accurately by the sonotrode.

At the same time, the special division prevents damage to the material in the area of the parting lines. Together with the soft casting resin, the fixture reliably prevents visual impairment of the components.

From the first idea to the development of an application right up to process optimization, we will work out the best possible solution with you, hand-in-hand.

Use our know-how and optimize your projects too!

Joint trials in the ultrasonic lab

In order to weld both components flush over the entire length, i.e. on block, the welding process was jointly developed and optimized in an extensive DOE process with several evaluation loops. Primarily the joining speeds graphical representation is used to optimize the process.

The tests were carried out in Herrmann's PLASTICS ultrasonic laboratory as well as at the customer's site, and some of them were transmitted via live video. Ultimately, it was also thanks to the close cooperation that the right parameters could be defined to ensure a strong and visually flawless joint under the demanding specifications.

About the Bosch FreshUp

The Bosch FreshUp uses Bosch Plasma Technology to remove unpleasant odors, bacteria and viruses from dry clothes without the need to wash them. When the plasma source is activated, the air is ionized directly at the clothing and electrodes are accelerated. Molecular chains are broken and bacteria and viruses are destroyed. This permanently neutralizes odors without the use of chemicals.

All components considered

The development of an ultrasonic welding solution for BSH proved how crucial the design of an individually optimized fixture is, in addition to determining the welding parameters. With the right materials and design, it makes a significant contribution to ensuring that components can be joined together not only strongly, but also with a flawless appearance.

Images: Herrmann Ultraschall / BSH Hausgeräte GmbH